Robotic De-Palletizer Machine

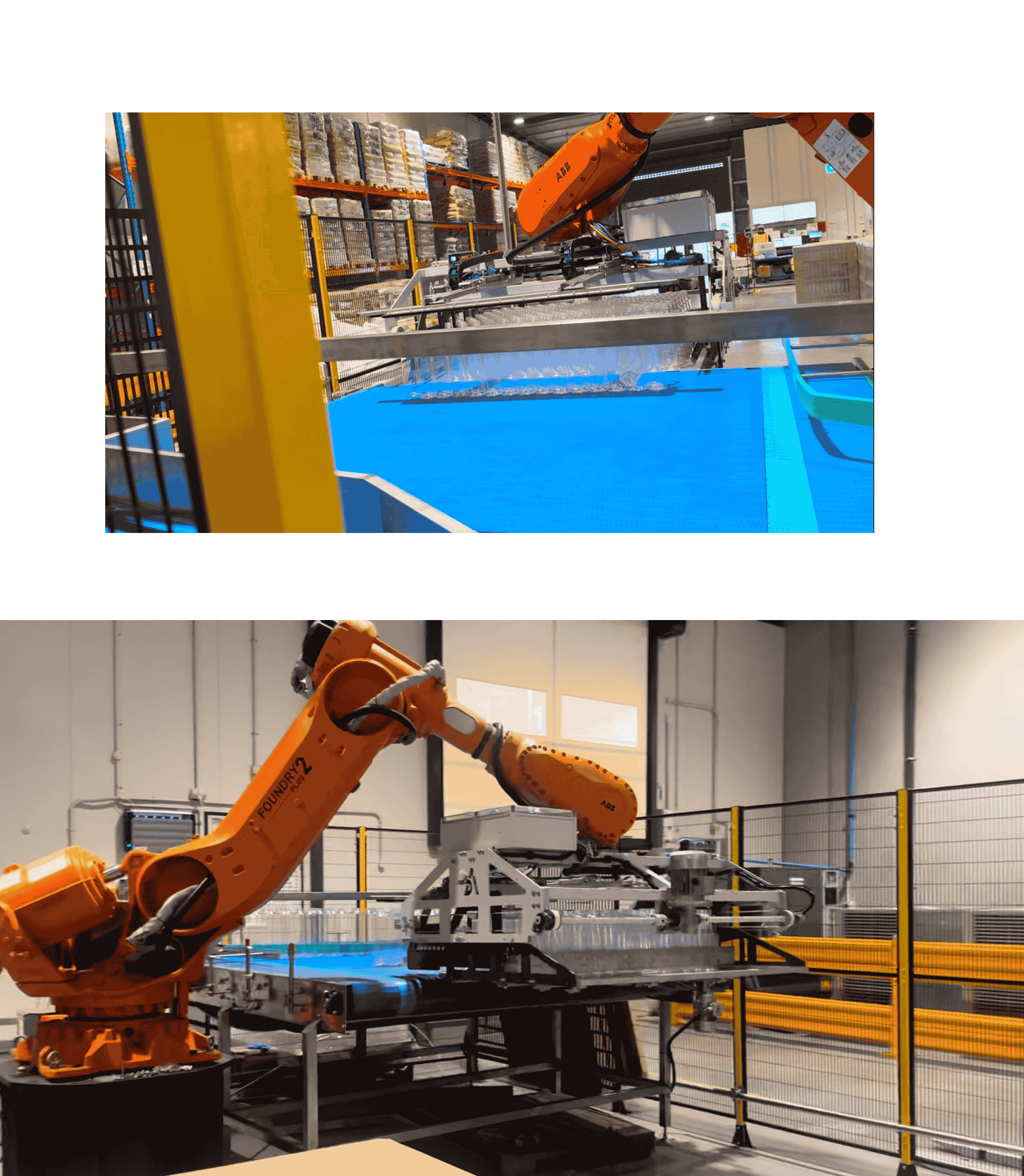

The Robotic De-Palletizer by MEF is an advanced automation solution engineered to streamline the unloading of pallets in high-volume operations. Capable of handling bottles, cartons, bags, shrink-wrapped bundles, and trays, it transfers products safely from pallets to conveyors or filling lines with precision and care. Designed with a compact footprint, intelligent HMI, and recipe-based layer programming, the system ensures continuous product flow, reduced manual handling, and lower risk of breakage. Trusted by food, pharmaceutical, cosmetic, and FMCG industries, MEF’s de-palletizer improves efficiency, enhances workplace safety, and integrates seamlessly with upstream fillers, case packers, and cartoners to deliver a complete, Industry 4.0 ready packaging line.Why Choose MEF De-Palletizers?

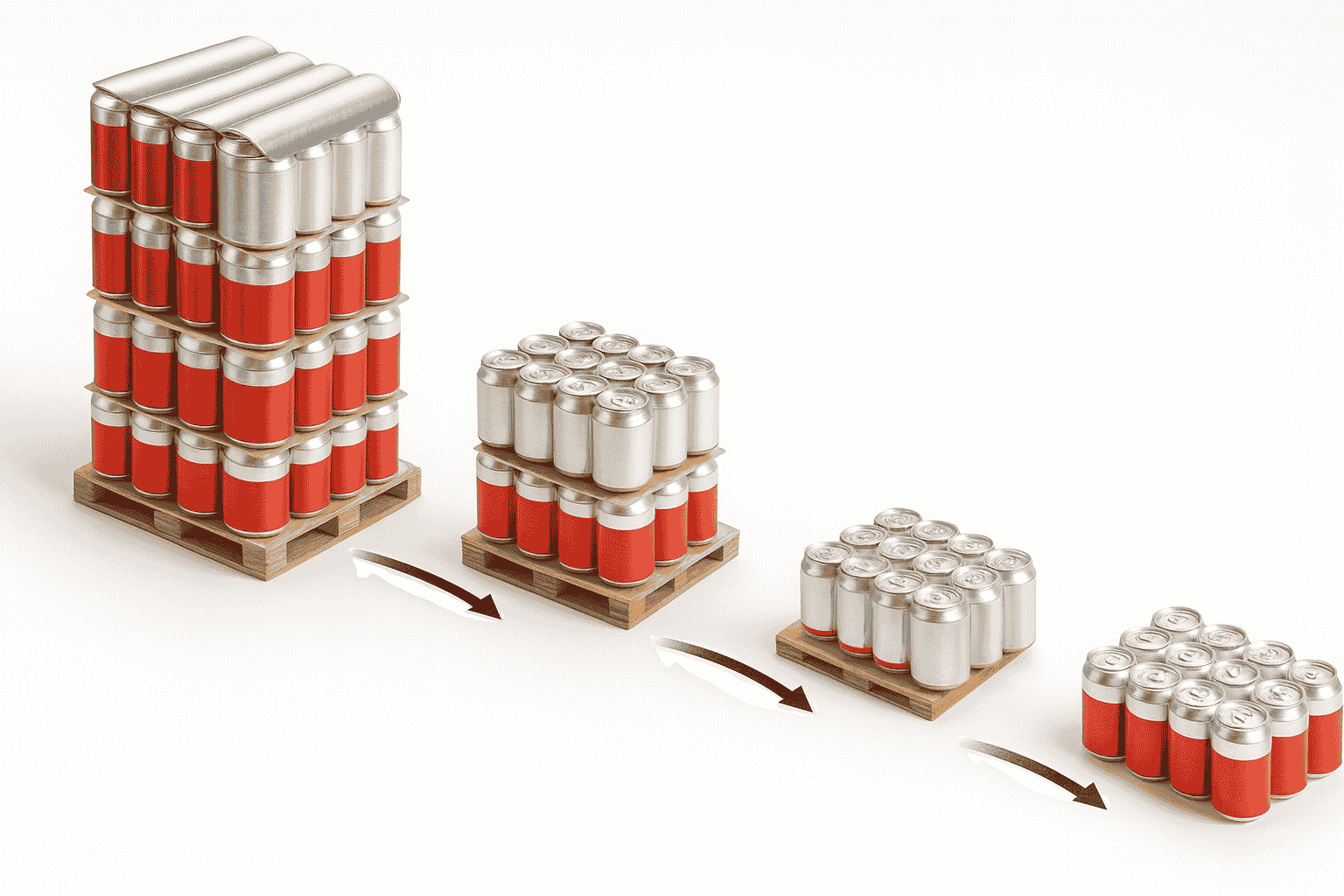

Automated Pallet Unloading

The MEF robotic de-palletizer automates the removal of bottles, cartons, bags, and shrink packs from pallets, feeding them directly into conveyors or filling lines for smooth production flow.

Gentle Product Handling

Equipped with custom vacuum, mechanical, or hybrid grippers, the system ensures safe handling of glass bottles, PET containers, and fragile cartons, minimizing breakage and product loss.

High Throughput

Designed for demanding operations, MEF de-palletizers can process up to 8–10 layers per minute, keeping pace with high-speed packaging and bottling lines.

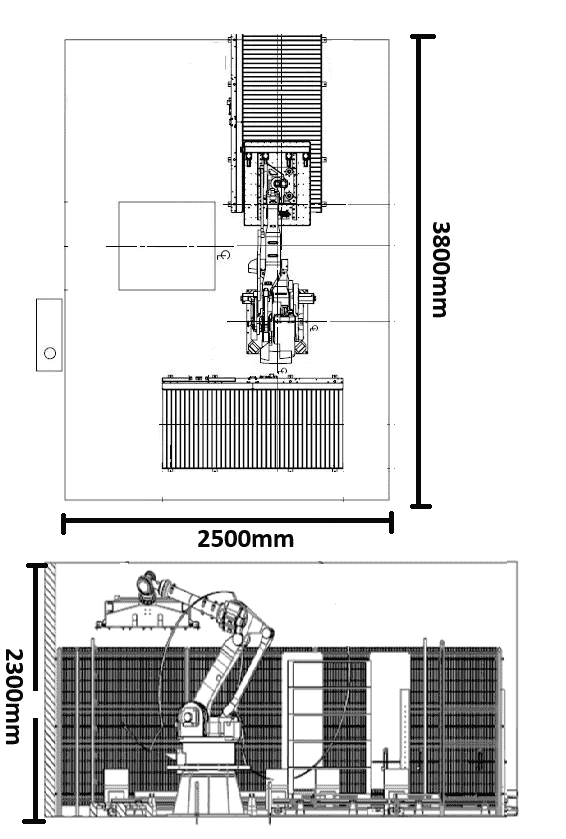

Compact & Modular Cell

With a space-efficient footprint and modular design, MEF robotic de-palletizers are ideal for both new projects and retrofits in facilities with limited floor space.

Safe & Ergonomic

By eliminating manual unloading, the system enhances operator safety, reduces repetitive strain, and lowers workplace injury risks in production environments.

Seamless Line Integration

Integrates effortlessly with case packers, cartoners, fillers, and conveyors, ensuring reliable material flow from pallet to packaging line.

Industry 4.0 Compatible

Featuring PLC controls, recipe-driven programming, and remote diagnostics, MEF de-palletizers support predictive maintenance and smart factory operations.

Proven in pharmaceutical, food, beverage, cosmetic, and FMCG industries, MEF robotic de-palletizers deliver safe unloading, consistent performance, and efficient end-of-line automation.

Technical Specifications

| Material of Construction (MOC) | Heavy-duty SS304 frame with optional SS316 contact parts for hygienic applications in food & pharma industries. |

|---|---|

| Depalletizing Speed | Up to 8–10 layers/min (varies with product type, pallet height, and robot configuration). |

| Robot Control | Powered by ABB/Siemens/Allen-Bradley controllers with touchscreen HMI, recipe-driven programming, and remote diagnostics. |

| Power Requirement | Approx. 5.5–6.0 kW depending on payload and gripper system; 415 V, 3-phase, 50 Hz. |

| Compressed Air | 6 bar supply for vacuum cups, pneumatic grippers, and layer-handling devices (Festo/SMC components). |

| Payload Capacity | Handles up to 40 kg per pick, suitable for bottles, cartons, shrink packs, and bags. |

| Pallet Compatibility | Supports Euro pallets, industrial pallets, and custom sizes (800 × 1200 mm, 1000 × 1200 mm, etc.). |

| Changeover | Recipe-based layer selection with HMI interface; no mechanical changes required for different SKUs. |

| Machine Weight | Approx. 2,000–2,600 kg depending on robotic arm size, gripper type, and safety cell layout. |

| Design Features | Compact robotic cell with CE-certified safety fencing, modular layout, and ergonomic operator access for quick maintenance. |

Optional Features

- Custom vacuum, mechanical, or magnetic grippers for bottles, cartons, shrink packs, and bags

- Automatic pallet infeed and discharge conveyors for continuous operation

- Layer detection sensors and vision systems for precise product positioning

- Slip-sheet and layer-sheet removal units for faster depalletizing

- Empty pallet stackers for automated pallet handling

- Industry 4.0 enabled controls with remote diagnostics and data logging

Integration with Packaging Lines

The MEF Robotic De-Palletizer connects seamlessly with upstream fillers, case packers, and cartoners, while transferring products onto conveyors for smooth downstream operations.

Explore: Case Packers · Cartoners

Watch our robotic De-Palletizer on action

Brand: MEF › Category› Secondary Packaging › Cartoning Machines

Key Features of MEF Robotic De-Palletizers

- Automated pallet unloading: Efficiently removes bottles, cartons, shrink packs, and bags from pallets with robotic precision.

- Gentle handling technology: Custom-designed vacuum, mechanical, or hybrid grippers protect glass, PET, and fragile packs from breakage.

- High-speed operation: Processes up to 8–10 layers/min, ensuring steady product flow to conveyors and fillers.

- Compact cell design: Space-saving layout suitable for both new facilities and retrofit projects.

- Intelligent HMI controls: Touchscreen interface with recipe-based layer programming, diagnostics, and live monitoring.

- Seamless line feeding: Direct integration with case packers, cartoners, and filling lines for uninterrupted packaging operations.

Need upstream automation? Explore our palletizers and case packers for a complete end-of-line solution.

- Reduced labor costs: Eliminates manual unloading and heavy lifting tasks.

- Improved workplace safety: Minimizes risks of injury from repetitive handling of heavy pallets.

- Product protection: Gentle robotic handling reduces breakage and packaging damage.

- Future-ready automation: Industry 4.0 connectivity, remote monitoring, and predictive maintenance features built in.

Applications

Ideal for high-volume industries requiring safe, accurate unloading from pallets to conveyors or processing equipment.

- Pharmaceutical bottles, vials, cartons, and shrink packs

- Food & beverage PET bottles, cans, bags, and trays

- Cosmetic jars, multipacks, and retail-ready cartons

- FMCG and consumer goods cases, mixed loads, and e-commerce packs

Key Details

- Depalletizing speed up to 8–10 layers/min

- Payload capacity up to 40 kg per pick

- Compatible with Euro and industrial pallet formats

- Energy-efficient robotic arm requiring ~5.5–6.0 kW

Industries & Applications

- Pharmaceutical & nutraceutical: Bottles, vials, cartons, and secondary packaging

- Food & beverages: PET bottles, shrink packs, cereal cartons, and snack bags

- Cosmetics & personal care: Jars, tubes, multipacks, and display-ready boxes

- FMCG & consumer goods: Household items, electronics, mixed-SKU depalletizing