Robotic Palletizer Machine

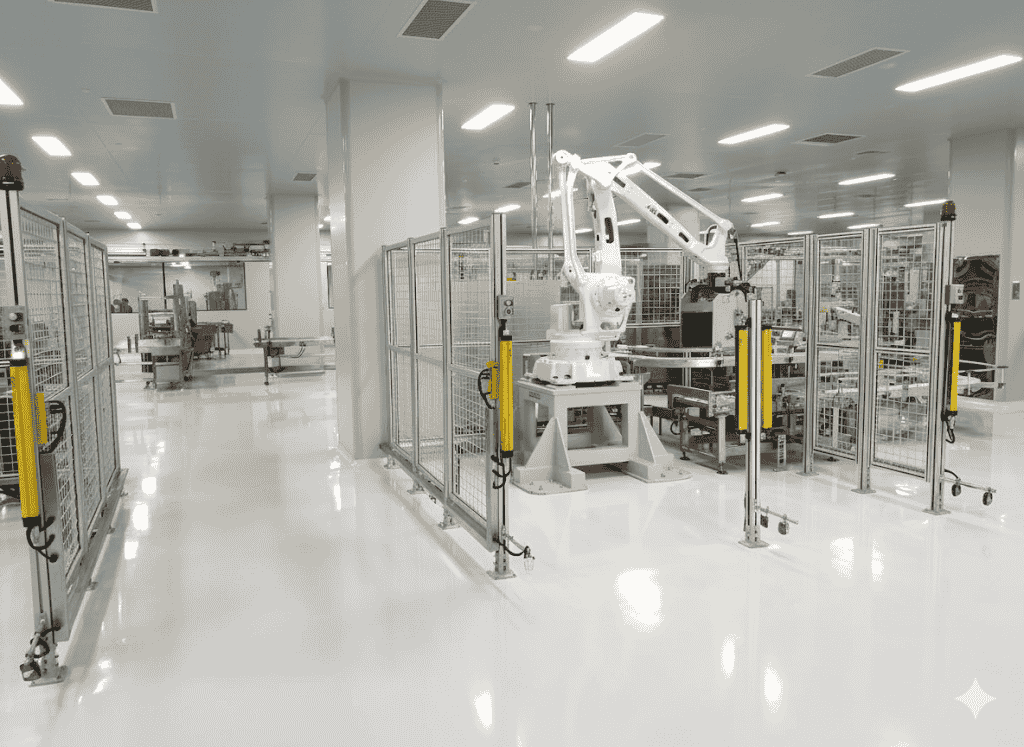

The Robotic Palletizer by MEF is a smart end-of-line automation system designed to improve efficiency, safety, and consistency in pallet stacking. Capable of handling cartons, bags, cases, shrink-wrapped bundles, and trays, it delivers precise and repeatable pallet patterns with minimal operator effort. Featuring a compact robotic cell, intuitive HMI, and recipe-driven programming, this solution reduces labor costs, enhances workplace safety, and adapts easily to multiple food, pharmaceutical, cosmetic, and FMCG packaging lines. With robust construction, high-speed robotic arms, and seamless integration with case packers, conveyors, and stretch wrappers, MEF’s palletizer ensures future-ready, Industry 4.0 compatible automation for modern production facilities.Why Choose MEF Robotic Palletizers?

Automated End-of-Line Efficiency

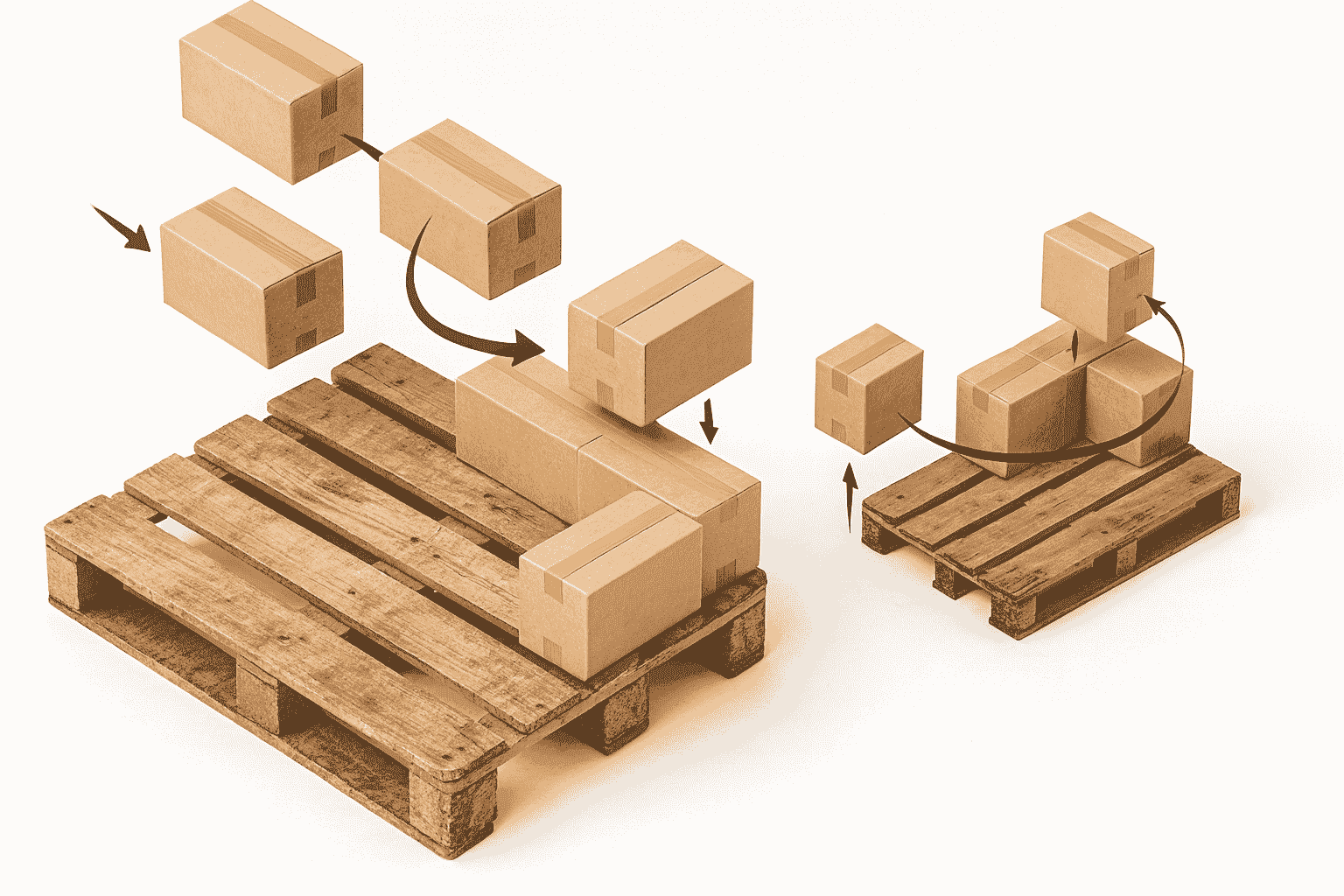

The MEF robotic palletizer eliminates manual stacking by automating pallet building for cartons, bags, cases, and shrink packs, ensuring faster throughput and consistent pallet quality.

Flexible Pallet Patterns

Configurable to handle single or multiple SKUs, the system allows quick recipe-based adjustments to pallet layouts, supporting retail-ready and warehouse-optimized patterns.

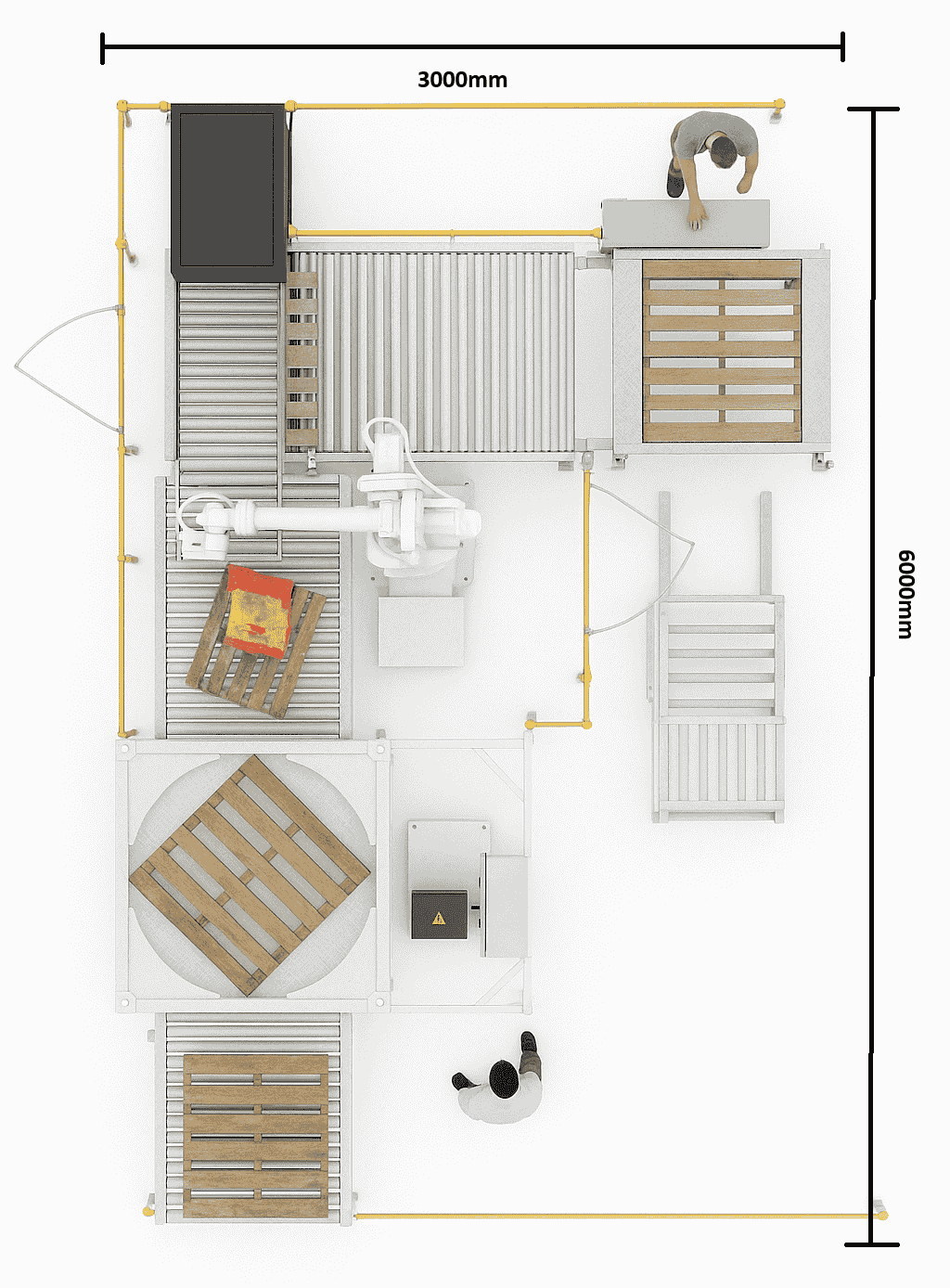

Compact Robotic Cell

Designed with a space-saving footprint, MEF robotic palletizers are ideal for new lines and retrofit projects where floor space is limited but high performance is essential.

Safe & Ergonomic

By removing the need for heavy lifting, robotic palletizing improves operator safety, reduces repetitive strain, and lowers workplace injury risks.

Seamless Line Integration

Works in sync with upstream case packers, cartoners, conveyors, and stretch wrapping systems, delivering a complete end-of-line solution.

Industry 4.0 Ready

Equipped with PLC control, data logging, and remote monitoring, MEF robotic palletizers are built for predictive maintenance and future-ready automation.

Durable & Reliable Build

Constructed with heavy-duty frames, ABB/Siemens/Allen-Bradley controls, and GMP-compliant design, the system ensures long-term reliability in demanding production environments.

Trusted across food, pharma, cosmetics, FMCG, and industrial packaging lines, MEF robotic palletizers deliver faster ROI, consistent pallet quality, and smarter end-of-line automation.

Technical Specifications

| Material of Construction (MOC) | Industrial-grade SS304 frame with powder-coated guarding; SS316 options for hygienic food & pharma environments. |

|---|---|

| Palletizing Speed | Up to 12 cycles/min (varies by load type, pallet pattern, and robot configuration). |

| Robot Control | ABB/Siemens/Allen-Bradley robotic controllers with touchscreen HMI, recipe storage, and remote diagnostics. |

| Power Requirement | Approx. 6.0 kW depending on payload and gripper style; 415 V, 3-phase, 50 Hz. |

| Compressed Air | 6 bar supply for pneumatic grippers, vacuum suction cups, and slip-sheet handling (Festo/SMC components). |

| Payload Capacity | Up to 50 kg per pick (configurable for cartons, bags, shrink-wrapped bundles, or trays). |

| Pallet Dimensions | Standard Euro and industrial pallets (800 × 1200 mm, 1000 × 1200 mm, or custom sizes). |

| Changeover | Recipe-driven pallet pattern selection via HMI; no mechanical adjustments needed for SKU change. |

| Machine Weight | Approx. 2,200–2,800 kg depending on robotic arm, gripper type, and cell layout. |

| Design Features | Compact robotic cell with safety fencing, CE-certified interlocks, ergonomic operator access, and modular design for multiple lines. |

Optional Features

- Custom gripper designs for bags, cartons, bottles, and shrink packs

- Automatic slip-sheet, layer sheet, or pallet dispenser modules

- Mixed-SKU palletizing for e-commerce & retail-ready shipments

- Integrated vision system for product orientation and quality check

- Stretch wrapper integration for complete end-of-line automation

- Industry 4.0 connectivity with real-time monitoring & predictive maintenance

Integration with Packaging Lines

The MEF Robotic Palletizer is designed to integrate smoothly with upstream case packers, cartoners, flow-wrappers, and conveyors, while linking downstream to stretch wrappers, warehouse management systems, and AGVs/AMRs.

Explore: Case Packers · Cartoners

Watch our vertical cartoner machine on action

Brand: MEF › Category› Secondary Packaging › Cartoning Machines

Key Features of MEF Robotic Palletizers

- Automated pallet building: Stacks cartons, bags, shrink packs, and cases with precise robotic control.

- Customizable pallet patterns: Recipe-driven layouts for single or multi-SKU shipments, easily adjustable via HMI.

- High-speed cycles: Achieves up to 12 picks/min depending on payload, gripper, and pallet configuration.

- Compact robotic cell: Space-efficient design suitable for both new installations and retrofits.

- Smart HMI controls: Touchscreen interface with pattern storage, quick changeovers, and live diagnostics.

- Seamless automation: Integrates with case packers, cartoners, conveyors, and stretch wrapping systems.

Looking for case packers or cartoners? MEF builds complete end-of-line packaging solutions.

- Durability: Built with heavy-duty frames and ABB/Siemens/Allen-Bradley controls for continuous operation.

- Safety first: CE-certified fencing, interlocks, and sensors keep operators protected.

- Efficiency: Robotic automation reduces labor costs and eliminates manual stacking errors.

- Future-ready: Industry 4.0 connectivity with remote monitoring, predictive maintenance, and data logging.

Applications

Designed for fast, reliable palletizing across industries where high throughput and consistency are critical.

- Pharma cartons, bottles, and shrink-wrapped cases

- Food & beverage bags, cartons, and multipacks

- Cosmetic jars, kits, and retail-ready boxes

- FMCG and consumer goods cartons, trays, and mixed-SKU loads

Key Details

- Palletizing speeds up to 12 cycles/min depending on payload

- Payload capacity up to 50 kg per pick

- Compatible with Euro and industrial pallet sizes

- Energy-efficient robotic arm with ~6.0 kW power requirement

Industries & Applications

- Pharmaceutical & nutraceutical: Cartons, bottles, vials, blister-packed products

- Food & beverages: Biscuit cartons, snack bags, cereals, shrink packs

- Cosmetics & personal care: Multipacks, display-ready cases, jars

- FMCG & consumer goods: Household items, e-commerce packaging, electronics